1.Fire proof & Insulation

Non-combustibility meets GB8624 Class A. The products will not ignite in a case of fire, and will not produce any toxic gas or smoke.

2.Waterproof and Moisure Proof

It can keep the stability in the semi open air and hot environment. it won’t be sinking or deformation.

3.Thermal Insulation and Sound insulation

High density and good sound insulation lead to be low coefficient of heat conductivity and goods heat-insulating property.

4.Safety and Harmless

The technical indexes of the board come within the national radiological protection standards for building materials. The actual test value is equal to the value of the lawn which is 20meters far way from the buildings.

5.Long use life

It is acid and alkali-resistance,anticorrosive, moisture proof and resistant to insect and termite. It will increase the strength and hardness as time passed as well which makes it has long use life.

Fiber Cement Board

Size

| Thickness(mm) | Width(mm) | Length(mm) |

| 5,6,8,9,10,12,15,18,20,24,25,30 | 608,1220 | 608, 1220, 2440,3000 |

Parameters

| Density Density: 1.2-1.6g/cm3 | Thermal conductivity ≤ 0.29 W/(m.k) |

| Bending strength(Parallel): ≥ 13 MPa | Moisture content: ≤ 10% |

| Water absorption: ≤ 40% | Moisture movement: ≤ 0.25% |

| Non-combustibility: class A | Asbestos: non asbestos |

Sanle fiber cement board is a new type of green environmental protection board with excellent performance for building and industry. It is an ideal decorative slab for exterior wall, partition wall and floor with excellent fireproof, moisture-proof, soundproof, Insect-resistant ant and durable features.

Its main raw materials are high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fiber and other minerals. According to a certain proportion of raw materials, the board is made through hatschek or flow slurry production technology , molding and autoclaved curing processes.

Sanle fiber cement board meets the national standard. There are middle and high density. Each process is strictly controlled to ensure that we can provide our customers with high quality products.

Features

Application

Sanle fiber cement board can be used for all kinds of ceiling, partition wall, exterior wall ,floor, decorative wall board bottom panel and etc. It is widely used in offices, hotels, hospitals, factory buildings, schools, villas, theaters and various art buildings.

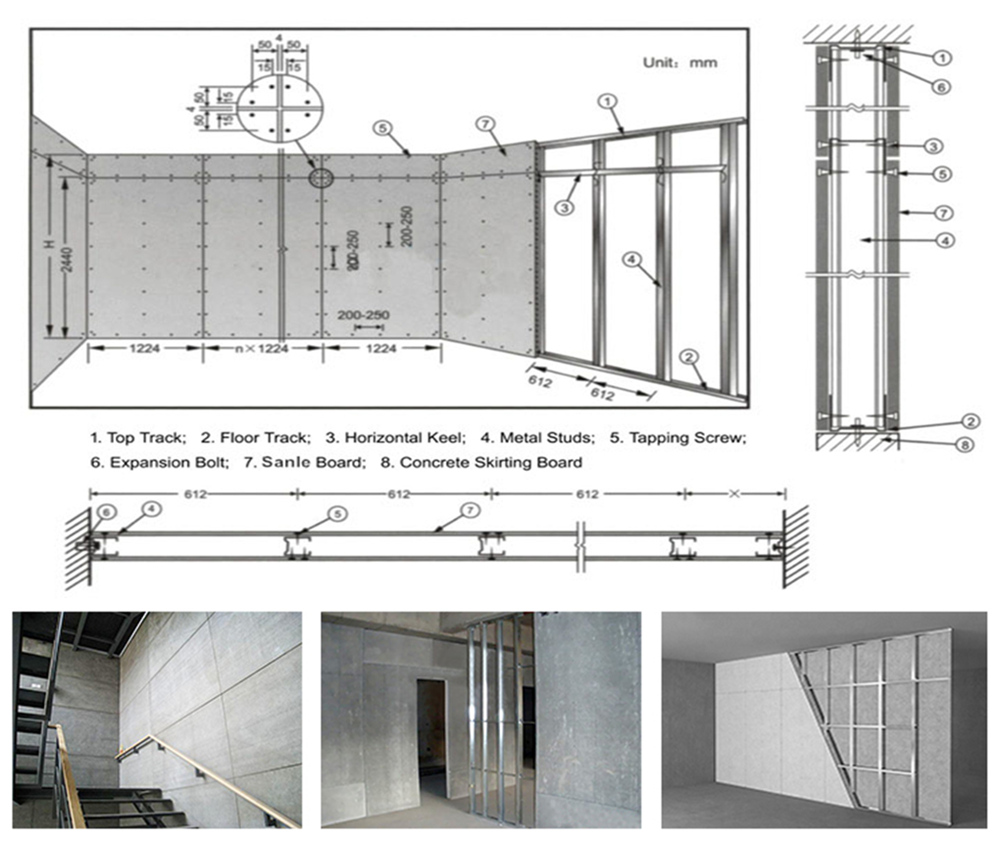

Partition Wall Installation

1. The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

2. The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

3. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

4. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

5. The expansion seam of about 4mm between boards should be kept.

6. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

7. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

Floor Board Installation

Selection of steel structure keel:

1. The span is within 8m: 15H steel for the main beam, #10 channel beam and #63 angle iron for the secondary beam.

2. No embedded parts shall be fixed with expansion bolts.

3. Abundant space can be used upper and lower beam structure, space is not enough can be used plane structure.Steel structure welding requirements: There are must be at least three sides of the welding, the top surface can not be welded.

1. Before laying the boards, the welding seam on the top surface must be polished flat and the welding spatter must be cleared away.

2. The longitudinal direction of the boards should be parallel to the main beam.

3. Any edge of the board shall not be suspended.

4. A gap of 3-5mm must be left between the boards.

5. The joint between the boards should be located in the center of the beam.

Nailing requirements:

1. Selecting the countersunk head tapping screw, with size of M5*45mm, nailing on the vice-keel (Angle iron).

2. Drill first and then nail, nail hole should be bigger than the diameter of the nail.

3. Nailing starts from the center of the board, and then hits outwards, and finally hits the side nails.

4. The nailing position of the side nail should be about 20mm from the edge of the board.

5. The nail distance is 300-600mm. Treatment of the joint: the joint can be injected with silicone sealant, or mortar can be used.

Follow-up processing:

1. Brushing waterproof coating, and then directly use.

2. Laying wood floor

3.Laying ceramic tiles

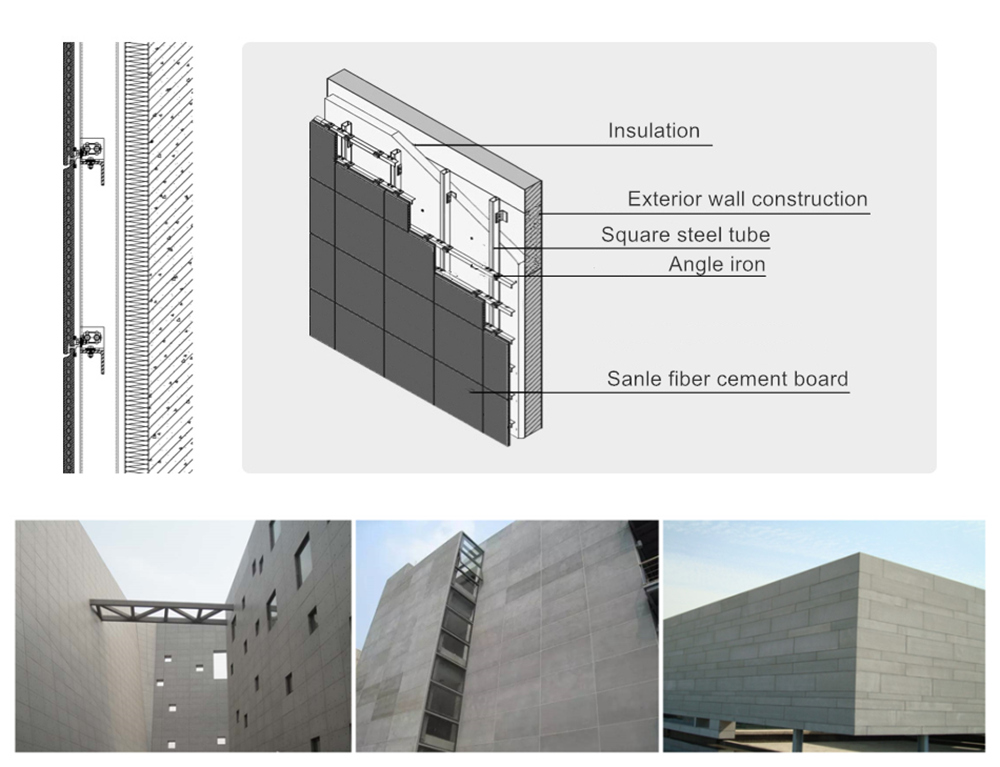

Exterior Wall Installation

1. Fiber cement board preparation: according to the size and design requirements, installing the supporting aluminum accessories( six aluminium accessories per sheet) on the back of fiber cement board ( maximum cross section size is 2780 * 1220 mm). Making cross line according to the vertical distance ( 600 mm ) between the transverse keels and length of fiber cement board uniform size, then fixing supporting aluminum fasteners at the intersection,using 10 mm long and 4 mm thick stainless steel screws.2. Construction wall preparation: cleaning up the wall surface, and then marking out the position lines and partition lines of the steels according to the design drawings and actual needs.

3. Wire hanging: vertical wire hanging should use the ∮1.0-∮1.2 size steel wire, with 8-10 kgs weight lower counterweight iron, and the upper end is hung on the special wire hanging Angle iron frame. The angle iron frames are fixed on the top corners of the wall with expansion bolts, and marking on the top and bottom of the control line.

4. Keel installation: first fixing 50×50×4 angle iron (with adjustable hole) on the structural surface with ∮8 expansion bolt, that horizontal distance between the angle iron and the 50×50×3.5 vertical square steel tube on the angle steel is 800mm. When installing the vertical square steel tube, it must be checked by hanging steel wire from top to bottom to detect its Perpendicularity. After that, installing the fastening angle iron and the transverse aluminum keel (with 600mm spacing). The connection between angle iron, square steel tube and transverse keel is made with ∮10 bolts. Last, using the infrared level meter to detect whether the horizontal aluminum keel is horizontal, and the steel line to detect whether it is vertical.

5. Fiber cement board installation: mounting the advance processing board on the keel according to the design drawings, and using aluminum accessories to connect the panel and keel. Hanging lightly the same level layer fiber cement boards on the keel, and then adjusting the horizontal and vertical degree of board through upper and lower steel wires. After that, checking the boards seam, whose width should be uniform according to the requirements of design. Last, tightening the stainless steel screws (20mm long and 6mm thick) on the complete set of aluminum accessories.

6. Board joint treatment: using the fiber cement board powder mixing glue to fill the seam, and then painting with special coating twice. When filling the gap, it is necessary to pay attention to the uniform and full filling.

Recommend Products

-

Calcium Silicate Board

Size Thickness(mm) Width(mm)

-

Calcium Silicate Ceiling Tiles

Size Thickness(mm) Width(mm)

-

Perforated Plate

Size Thickness(mm) Width(mm)

-

Fiber Cement Board

Size Thickness(mm) Width(mm)

-

low density calcium silicate board | Low Density Fireproof Calcium Silicate Board

Size Thickness(mm) Width(mm)