Calcium Silicate Board

Size

| Thickness(mm) | Width(mm) | Length(mm) |

| 4.5、6、8、9、10、12、15 | 608,1220 | 2440,3000 |

Parameters

| Density : 1.2-1.6 g/cm3 | Thermal conductivity ≤ 0.29 W/(m.k) |

| Bending strength: ≥ 9 MPa | Moisture content: ≤ 10% |

| Wet expansion: ≤ 0.25% | Water absorption: ≤ 40% |

| Incombustibility: class A | Asbestos: non asbestos |

Calcium silicate board is a new type of green environmental protection board with excellent performance for building and industry. It is an ideal decorative slab for ceiling and partition with excellent fireproof, moisture-proof, soundproof, Insect-resistant ant and durable features.

Its main raw materials are high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fiber and other minerals. According to a certain proportion of raw materials, the board is made through hatschek or flow slurry production technology , molding and autoclaved curing processes.

Sanle calcium silicate board meets the national standard. There are low, middle and high three kinds densities. Each process is strictly controlled to ensure that we can provide our customers with high quality products.

2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Its main raw materials are high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fiber and other minerals. According to a certain proportion of raw materials, the board is made through hatschek or flow slurry production technology , molding and autoclaved curing processes.

Sanle calcium silicate board meets the national standard. There are low, middle and high three kinds densities. Each process is strictly controlled to ensure that we can provide our customers with high quality products.

Features

1. 100% Asbestos Free

2. Fire Resistance and Moisture Resistance

3. High Strength and Good Stability

4. Anti Fungus and Antiseptic

5. Waterproof and fireproof

6. Easy working

7. Anticorrosive

Applications

Sanle calcium silicate board can be used for all kinds of ceiling,partition, EPS board surface panel and composite wall board bottom panel and etc.

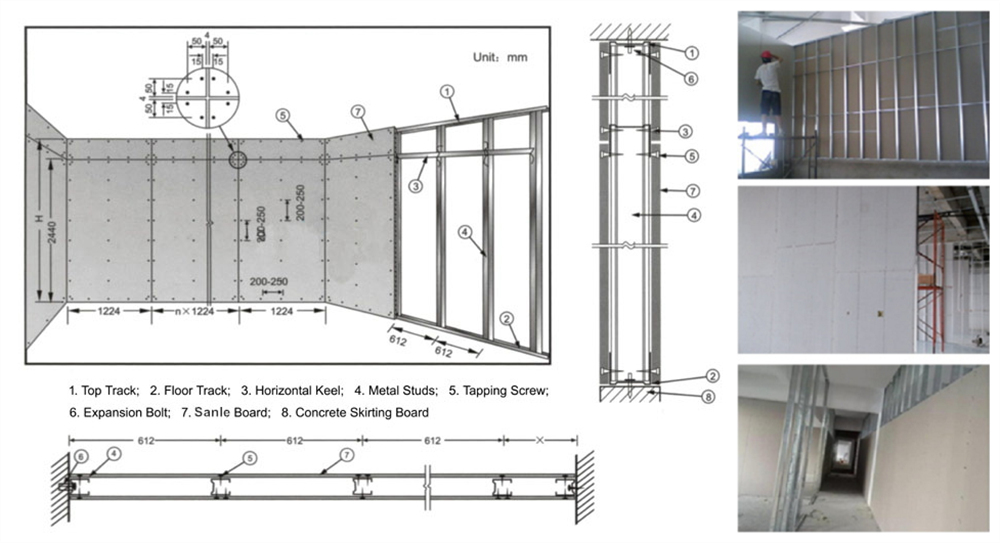

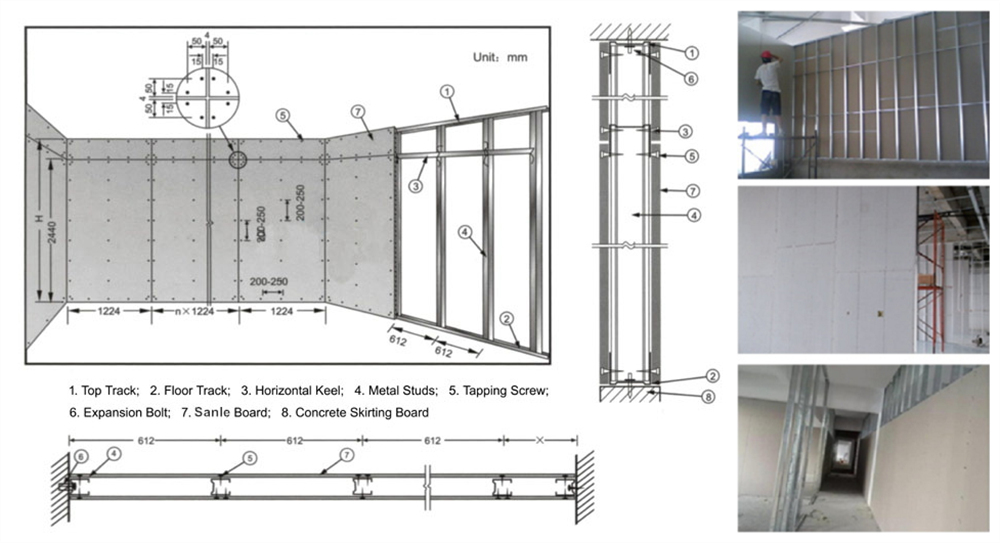

Partition Wall Installation

1. The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

2. The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

3. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

4. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

5. The expansion seam of about 4mm between boards should be kept.

6. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

7. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

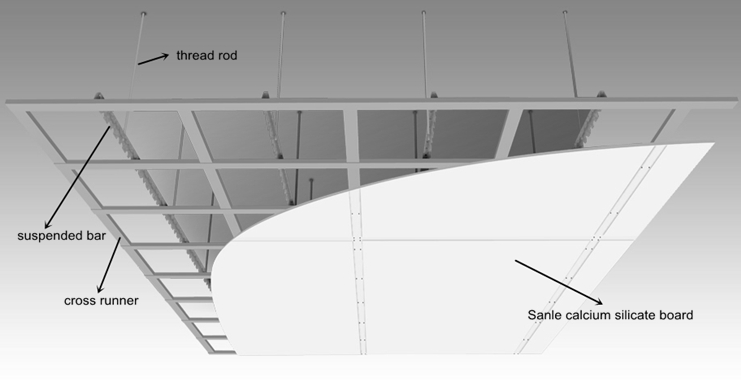

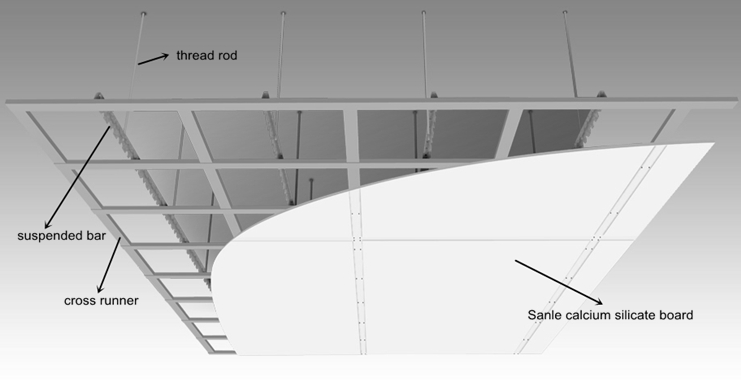

Ceiling Installation

1.Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Recommend Products

-

Calcium Silicate Board

Size Thickness(mm) Width(mm)

-

Calcium Silicate Ceiling Tiles

Size Thickness(mm) Width(mm)

-

Perforated Plate

Size Thickness(mm) Width(mm)

-

Fiber Cement Board

Size Thickness(mm) Width(mm)

-

low density calcium silicate board | Low Density Fireproof Calcium Silicate Board

Size Thickness(mm) Width(mm)